Factory Cheap Hot PLA Thermoforming Equipment - QZC46-71/ 54-CWF3 3 Stations Thermoformer – Mengxing

Factory Cheap Hot PLA Thermoforming Equipment - QZC46-71/ 54-CWF3 3 Stations Thermoformer – Mengxing Detail:

Machine Details

Usage

The machine is suitable for making all size packing containers ,in open-type with thin-wall ,by using roll-sheet , under high-speed vacuum suction-forming processing .The products out of this machine can be used for the package of foods .native-products, tourist-goods, textile, medical, toy, cosmetic, electrical elements and daily used hard-ware ,etc .

Sheet fit to the machine

Starch-deposit sheets ,light-deposit sheet ,environment sheet APET ,PETG .Color sheets ![]() VC,HIPS,PET,PS,PP, CPET,EPS, etc. Fiber-coating-sheet.

VC,HIPS,PET,PS,PP, CPET,EPS, etc. Fiber-coating-sheet.

Feature Function

1. Mechanical , Pneumatic and Electrical Combination . All working action is controlled by PLC . Touch Screen Input , easy and convenient .

2. Three Working Position : Forming / Cutting / Stacking .

3. Pressure / Negative Forming assist with Plug

4. Upper or Lower Mold Forming Method

5. Servo Motor Feeding , Feeding Length Stepless Adjust , High Speed and Accurate .

6. Upper Heater , Four Section Heating .

7. Heater with Intellectual Temperature Control System , automatic supply the heating, Individual Heater Control , Touch Screen Digital Input , Mini-adjust & Precision and Accurate , Fast Heating ( Only 3 min from 0-400 degree ) . Stable and Reliable .It won’t effect by outer voltage , lower power consumption , longer life of far infrared ceramic heater .

8. Servo Motor Stacking , Finished Production Accounting .

9. All production data and technical parameter store and recall function .

10. Edge Automatic trimming .

11. Feeding China Width separate adjust or Motor adjust .

12. Heater automatic push-out function .

13. Auto Roll Sheet Loading , Reduce the Working labor.

Technical Components

|

PLC |

Taiwan Delta |

|

Touch Screen Monitor ( 10.4″inch /Color ) |

Taiwan Delta |

|

Feeding Servo Motor(3.0kw) |

Taiwan Delta |

|

Stacking Servo Motor (1.5kw) |

Taiwan Delta |

|

Heater (78PCS ) Heater |

CHINA |

|

Solid State Relay (78 PCS ) |

CHINA |

|

Contactor |

Germany Siemens |

|

Thermo Relay |

Germany Siemens |

|

Relay |

Germany Weidmuller |

|

Vacuum Pump |

Busch R5 0040 |

|

Pneumatic |

JAPAN SMC |

|

Cylinder |

CHINA |

Technical parameters

|

Sheet Width (mm) |

460-710 |

|

|

Sheet Thickness (mm) |

0.2-1.5 |

|

|

Max Roll Sheet (mm) |

600 |

|

|

Forming Mold Stroke (mm) |

2×155 |

|

|

Cutting Mold Stroke (mm) |

155 |

|

|

Cutting Base Stroke (mm) |

Max 100 |

|

|

Max Forming Area (mm2) |

670×540 |

|

|

Max Forming Depth / Height (mm) |

80/50 |

|

|

Max Cutting Force(kgf) |

30000 |

|

|

Working Capacity ( Cycle / min) |

4-18 ( Max capacity is 18 Cycle/ Per Min ) |

|

|

Forming Cooling |

Water Cooling |

|

|

Air Source |

Air (m3/ min) |

≥5 |

|

Air Pressure (MPa) |

0.8 |

|

|

Vacuum Pump |

Busch R5 0040 |

|

|

Power |

3 Phase 4 Line 380V50Hz |

|

|

Heater (kw) |

44.2 |

|

|

Max Power (kw) |

50.42 |

|

|

Max Dimension (L×W×H) (mm) |

9400×3030×2430 |

|

|

Max Weight (kg) |

≈9000 |

|

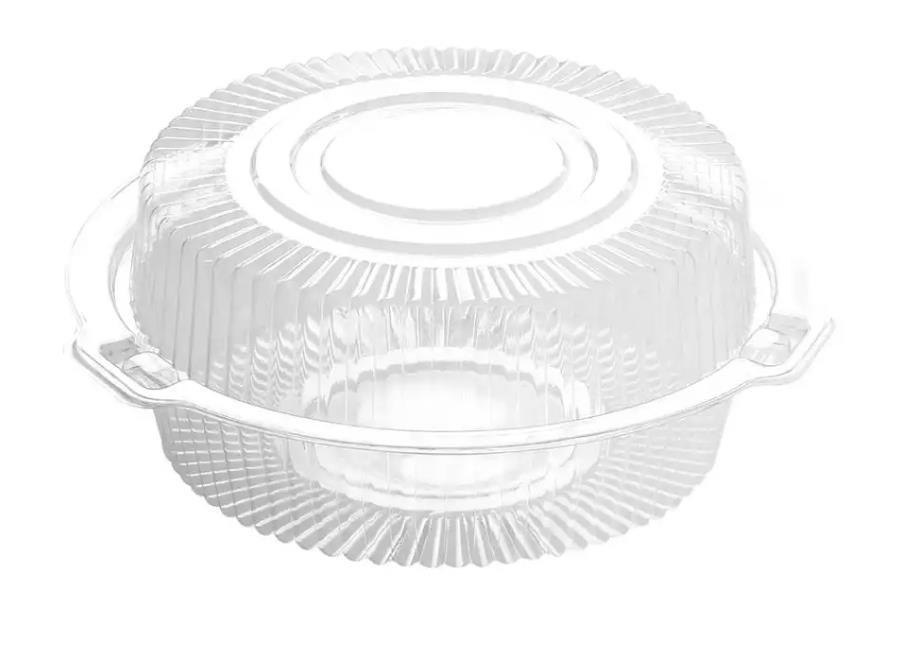

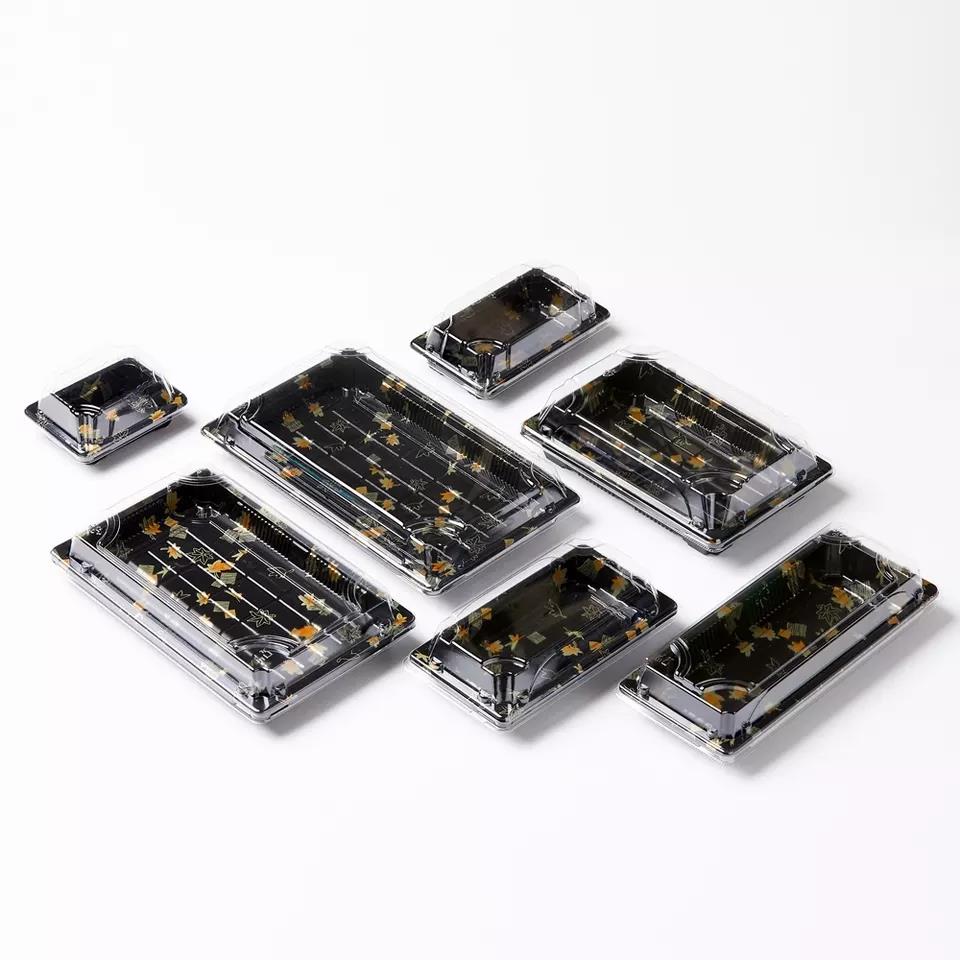

Sample Pictures

Container Pictures

Product detail pictures:

Related Product Guide:

We emphasize development and introduce new products into the market every year for Factory Cheap Hot PLA Thermoforming Equipment - QZC46-71/ 54-CWF3 3 Stations Thermoformer – Mengxing , The product will supply to all over the world, such as: Bangalore, Seattle, French, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.